Product

ClassifyProduct

-

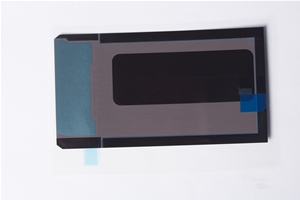

OLED foam …

-

OLED cushi…

-

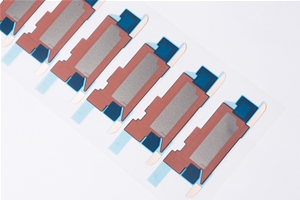

Graphite S…

-

Conductive…

-

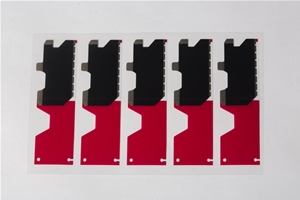

Shielding …

-

Shielding …

-

AOD100 Onl…

1. Highly optimized, stable and high-intensity overall design with low noise and vibration; 2. Equipped with Nordson EFD contactless spray dispensing valve, easy maintenance (body cleaning within 10 minutes), with high speed, high precision, contactless damage, applicable to a wide range of glue and other obvious advantages, at the same time, it can cope with micro, quantitative dispensing, ultra-narrow glue line, ultra-small space dispensing and other processes. 3. Powerful intelligent control software function, ensuring the realization of various complex dispensing processes (such as dotting, line, frame, arc, circle, filling and sealing glue, etc.) in high-speed movement, and equipped with various auxiliary modules (such as weighing system, height measuring system, nozzle cleaning, track preheating and other functional modules).

-

PZT100 Hig…

Can fit acoustic sound film ball top, back glue, PI, bar code and other high-precision accessories, suitable for all kinds of special-shaped materials; High-precision linear motor is adopted for X and Y axes. The equipment platform is marble platform, with high fitting precision and the highest fitting precision is ±0.025mm. Y-axis linear motor adopts double action, mounting head and upper camera stagger action, fast speed; Multi-function feeding feida, the maximum width of the material belt is 80mm, the discharging mode supports 1 output 8; The built-in pipeline can be used for single production or online production of multiple machines. It can be connected with other process equipment in series. The pipeline height is 900±30mm. When the equipment and other process equipment line production, the fixture can be installed back flow.

Copyright:Dongguan Tarry Electronics Co., Ltd.

ICP:粤ICP备19149949号

Technical support:华企立方